Polypropylene Tank Manufacturing

Polypropylene, a thermoplastic type commonly used in many fields in the world, is obtained by passing propylene through various polymerization processes with advanced technology. This material, which plays an important role in the plastics industry, has also been used in many fields such as engineering, electronics, kitchen tools, installation materials. It is also an ideal polymer material for the production of highly resistant polypropylene tanks. The fact that it is a very durable material and its cost is cheap, has prepared the environment for its frequent preference in this field.

This material with low friction coefficient and good electrical insulation is also very resistant to chemicals.

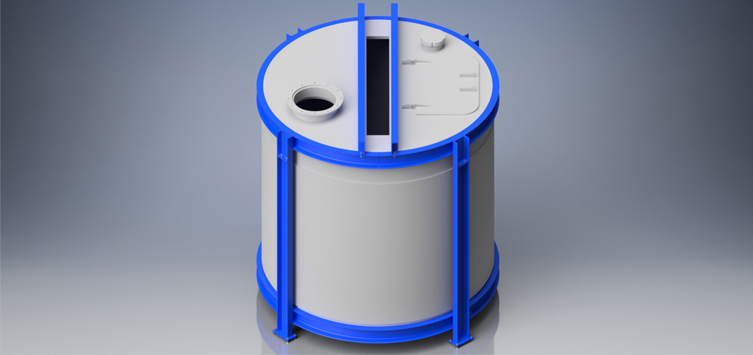

Resistant to voltage breaks.Due to the excellent processability of polypropylene, tanks used in many sectors are manufactured. These tanks are suitable for the storage of petroleum and derivatives, fuel, chemical materials. Mixing needs are also provided with mixer tanks. With serpentine tanks, heating or cooling of the material in the tank can be ensured through the pipes mounted on the inner and outer surface.

Polypropylene tank manufacturing is carried out according to the request of the person. Desired geometric shapes; vertical or horizontal cylinders, rectangular prism shaped tanks are designed. Material thickness can also be adjusted according to the product to be preserved.The size and volume are also arranged according to the needs of the recipient. Polypropylene tanks have good resistance to high pressure and temperature. In this respect, it can be said to be better than polyethylene tanks. However, it is still recommended that these tanks are not exposed to extreme high temperatures and pressures for a long time.

Because such situations can shorten the life of the tank. Otherwise, polypropylene tanks can be used up to 50 years if they are not exposed to too high temperature and pressure,Polypropylene tanks serve for purposes such as storing, mixing, heating and cooling large volumes of materials, which can withstand weather conditions, can be carried easily, without deterioration and wear.

Teknik plastik firması uzman kadrosu, 20 yıllık tecrübesi ve konusunda sahip olduğu kurumsal referanslarıyla, standart ve özel tiplerde tank imalatlarınla sektöründe lider konumdadır.

Teknik plastik firması uzman kadrosu, 20 yıllık tecrübesi ve konusunda sahip olduğu kurumsal referanslarıyla, standart ve özel tiplerde tank imalatlarınla sektöründe lider konumdadır.