Polyethylene Tank Manufacturing

Polyethylene is a thermoplastic product with a wide range of uses. Polyethylene is named after ethylene in monomer form. It is called (PE) in the plastics industry. It is the most used type of plastic today. It is a type of plastic used in tubes, pipes, shampoo bottles, parquets, fuel oil bottles, kitchenware, garbage bag bags, engine oil bottles and some products. The reason why polyethylene is used so much is that it is manufactured cheaply and it is robust.

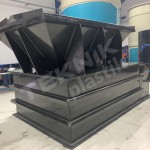

The most important feature of polyethylene is its use in tank manufacturing. It is the most preferred type of plastic in the manufacture of storage tanks. Thanks to the polyethylene tank manufacture, fuel oils, natural gas, water treatment and water storage are provided more easily. It is resistant to chemicals and is ideal for storing chemicals. It is highly resistant to acids and bases. It is an environmentally friendly plastic. It does not harm the environment.

It is a long-lasting product as long as it is used in accordance with the instructions. It is included in the group of recyclable materials and recycling is possible. It is resistant to high temperature and cold. Polyethylene tanks never damage the product inside the tank and prevent the product from depreciating. It has been subjected to many tests to verify that it does not contain any carcinogenic substances. It is produced in accordance with human health conditions. So it can be used with peace of mind. Water, which is the most important source of people, is purified with pipes made of polyethylene and is offered to people.

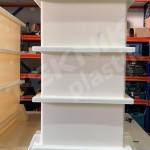

Polyethylene tanks are a preferred product in many sectors. Tanks that can serve the purposes of storage, mixing and heating-cooling with the manufacture of polyethylene tanks are in great demand. Polyethylene tanks are easy to clean. Maintenance can also be provided easily. Products can be protected with polyethylene tanks without spoiling or exposure to any chemicals. For many years, deterioration, wear and rust are not observed in these tanks.

Teknik plastik firması uzman kadrosu, 20 yıllık tecrübesi ve konusunda sahip olduğu kurumsal referanslarıyla, standart ve özel tiplerde tank imalatlarınla sektöründe lider konumdadır.

Teknik plastik firması uzman kadrosu, 20 yıllık tecrübesi ve konusunda sahip olduğu kurumsal referanslarıyla, standart ve özel tiplerde tank imalatlarınla sektöründe lider konumdadır.