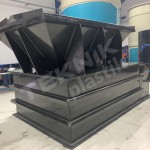

Hdpe Tank Manufacturing

Polyethylene is a type of thermoplastic with a wide range of usage. It is the most used type of plastic in today’s industry. The reason is that it has a robust and long-lasting structure. Shampoo bottles, bleach bottles, garbage bag bags, engine oil bottles in our house are always produced with polyethylene. The construction of polyethylene is obtained by polymerization in ethylene. It has no chemical harm. It has an important place in the plastic industry due to its cheap price. Polyethylene is durable and long-lasting against external environment and moisture. There are varieties of polyethylene. These;

High density polyethylene (HDPE): It is the closest chemical type to polyethylene. It has very low defects. In this regard, it does not affect the purity rate of polyethylene. In this respect, it has a high density.

Low density polyethylene (LDPE): It is the opposite of high density polyethylene. It is low density polyethylene because of its high crystallization rate. It is also very resistant to.

Very low density polyethylene: Structurally, it has a short chain structure branching content.

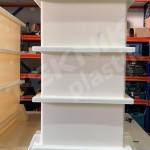

Teknik plastik firması uzman kadrosu, 20 yıllık tecrübesi ve konusunda sahip olduğu kurumsal referanslarıyla, standart ve özel tiplerde tank imalatlarınla sektöründe lider konumdadır.

Teknik plastik firması uzman kadrosu, 20 yıllık tecrübesi ve konusunda sahip olduğu kurumsal referanslarıyla, standart ve özel tiplerde tank imalatlarınla sektöründe lider konumdadır.